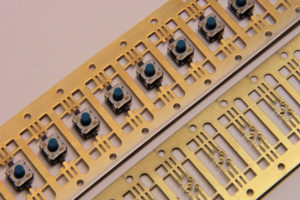

OMNI Engineering, Inc. was contracted to produce a series of stamped leadframes for use in various circuit boards due to our reputation for providing precision miniature and micro miniature stampings.

Manufacturing of these intricate parts is performed with carbide progressive dies in high speed 30 ton Bruderer presses, which are capable of holding tolerances of +/-0.0005”. The customer identified the pilot hole diameter, progression and camber as critical to their automated assembly operation. This we were able to hold in addition to dimensional tolerances of +/-0.0005”. Stamped leadframes are then plated with tin, palladium nickel, or gold, quality control is maintained through the use of our F.O.V. Smartscope (automated inspection system), dimensional, camber, and visual inspections. In addition to our own stringent quality standards, this project also requires compliance to Mil-Std-202 and ASTM B571 standards. We currently manufacture 50,000 to 500 million of these components annually.

To learn more about this project, or the processes used to manufacture it, see the table below or contact us directly.