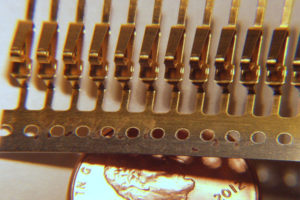

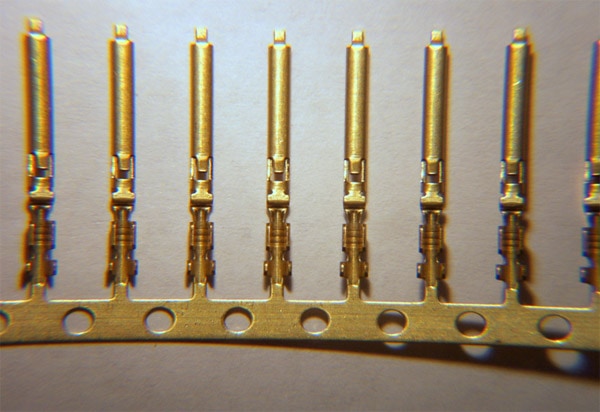

The products highlighted here exemplify OMNI Engineering, Inc.’s ability to manufacture multi part orders, with various process and quantities. These terminal, battery, board and interconnect contacts were precision stamped on high speed Bruderer presses with carbide progressive dies. Our production capacity allows for high volume stamping while holding very tight tolerances, in most cases tolerances of +/-0.0005”, and angular tolerances of +/- 1/2 degrees are achieved.

The base materials used for these electrical contacts range from beryllium copper, nickel silver, phosphor bronze, to brass. Various finishes are also required; the battery contacts are gold and tin plated, while the board contacts received a combination of gold, tin and matte tin plating, as well as nickel and electroplated nickel plating. The interconnect contacts required gold plating and bright 100% tin plating.

Maintaining quality for work with such a variety of specifications requires a robust quality program. All stamped components are subject to rigorous quality measures such as dimensional, camber, gage, visual, and gram force inspections, as well as use of our laser micrometer and our F.O.V. Smartscope (automated inspection system). The production process is monitored through the use of control logs and real time SPC data collection, with data supplied to the customer on every shipment.

We currently manufacture 50,000 to 500 million of these contacts in various configurations, with lead times of 2 to 4 weeks. For more information on these projects, or the processes used to manufacture them, see the table below or contact us directly.