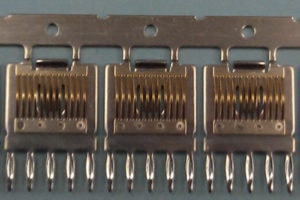

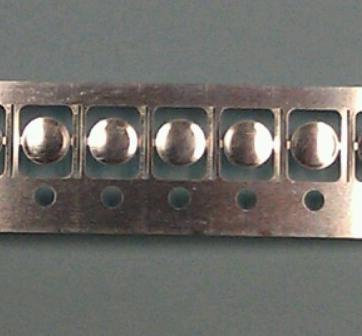

As medical devices become more advanced and complex, so too does the precision of their internal components. At OMNI Engineering, Inc., we specialized in precision miniature and micro miniature stampings that are ideally suited for the specific requirements of the medical industry. The quality program for the medical industry is an essential part of our process; through the use of control plans, real time SPC data collection and reporting that provides immediate process performance to the production department, to use of a video inspections system (OGP F.O.V. Smartscope), laser and digital micrometers, comparators, toolmakers microscopes and a variety of hand held tools that are controlled through our calibration system.

More customers are looking for suppliers who can provide not only the stamped components, but also secondary operations such as assemblies, heat treating or plating. At OMNI Engineering, Inc., we provided customized assemblies per the customer’s requirements, perform controlled atmosphere heat treating of beryllium copper products in-house, and work closely with plating sources across the country to meet customer needs for plated contacts in precious metals, tin and nickel.

To learn more about this project, see the table below or contact us directly.